On-demand Regulators, Bags for Calibration Tees?

In a perfect world there is nothing wrong with Bags or On-demand Regulators. However, we live in a world that is far from perfect. When used properly and they are functioning perfectly, you will always get the same result. In practice, we rarely see that.

Here are the common issues that we see:

On-demand Regulators

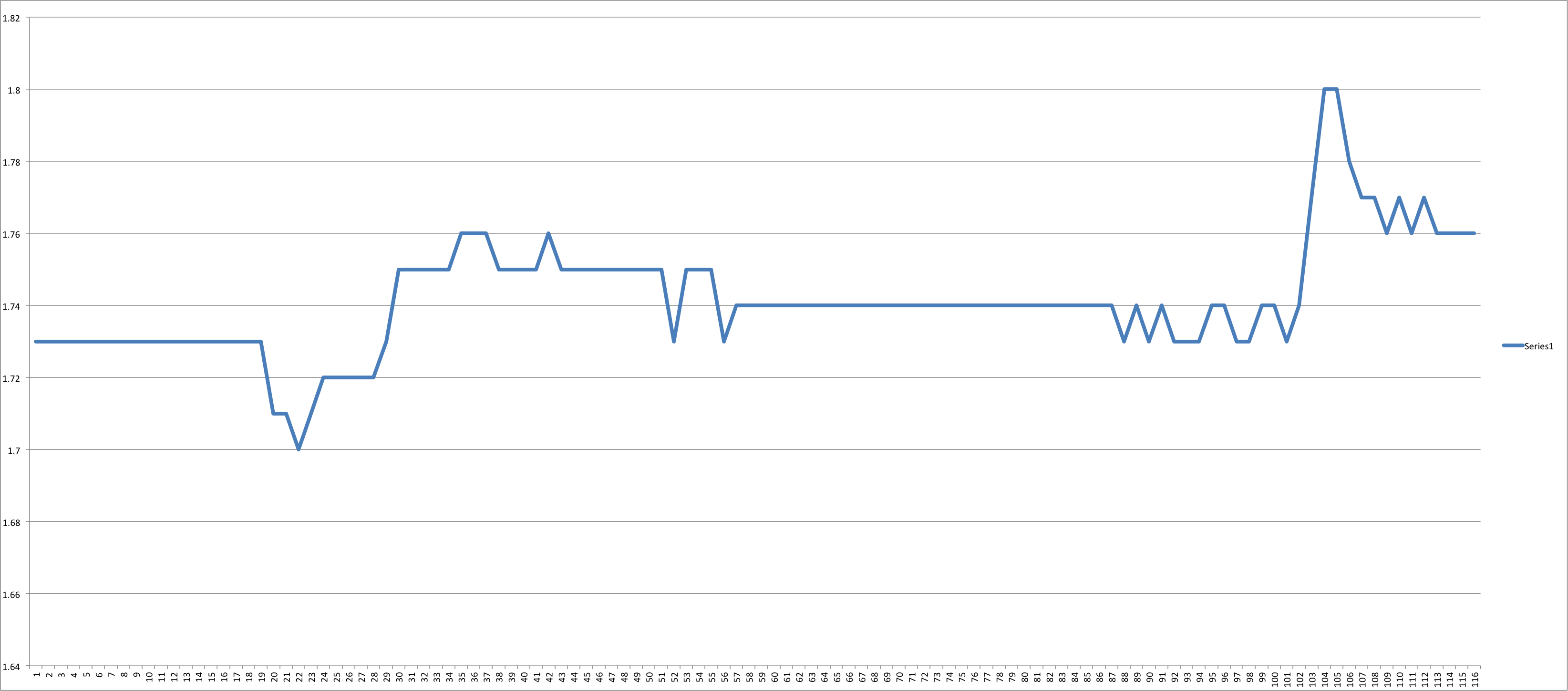

We regularly see markedly inconsistent crack pressures and then flow restriction. The image below shows a phx21 running on an On-demand Regulator:

Click the image to see a larger version

Click the image to see a larger version

The pressure should be 1.74-1.76 all the time but the inconsistent restriction makes the pump throttling run around and over shoot. A percent change in this restriction will be the same percentage of drift.

The main challenge here is that it is very hard to test if a regulator is going bad. Unless you have a vacuum gauge hooked to each regulator while you are calibrating and drifting, there is no way to know for sure that the restriction you are experiencing is constant.

Bag

The primary difficulty with using calibration bags is the uncertainty that is introduce into any quantitatively analytical process, such as the assessing the presence of a drift in the accuracy of the analyzer. For instance, there are a lot of ways to “correct” a drift that you don’t like:

- Squeezing the bag

- Resting a hand on the bag

- Pressurizing/overfilling the bag

- Refilling the bag

- Closing the valve just a little

- Getting a “fresh” bag

- Filling a bag with a different concentration

It would be challenging to explain any of the above actions to an auditor, let alone an agency inspector.

Calibration Tee

LDARtools has extensively researched the effect of split (Calibration) tees vs. other methods of applying calibration gases.

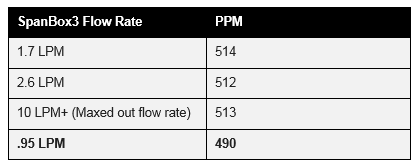

When you use the Calibration Tee, the sample flows past the opening to the probe so that the phx21 draws the sample that it needs and any excess simply passes by and out of the system. We ran a test using these:

- A phx21 (serial number: 1495)

- 500ppm Methane in Air

- phx21 flow rate .95 Lpm (This rate is self-adjusting based on the phx21’s computerized pump-throttling feature)

- Spanbox3 with Calibration Tee

By adjusting the flow rate at various levels with .95 as the baseline, we consistently achieve no distortion in the readings. For example:

Of course, if the flow rate on the SpanBox is less than the flow rate of the phx21 (.95 LPM) then you can get unpleasant results. That is why the LDAR Think Tank recommends that the flow rate on the SpanBox be set at 2 LPM. This is a one-time setting that takes mere minutes to make and requires no further maintenance.

Of course, if the flow rate on the SpanBox is less than the flow rate of the phx21 (.95 LPM) then you can get unpleasant results. That is why the LDAR Think Tank recommends that the flow rate on the SpanBox be set at 2 LPM. This is a one-time setting that takes mere minutes to make and requires no further maintenance.

So long as your supply regulator is operating properly and you have gas, then the flow will be an appropriate rate and you will achieve these results.

With a Calibration Tee there is only one variable: Is there excess flow through the Tee?

It really doesn’t even matter how much excess. While we recommend a flow meter check to minimize wasted gas and have documentable results, a quick check with your finger is, practically speaking, all that is needed to determine excess flow.

The split tee method of delivering the gas is, we believe, the optimal way to administer gas in the calibration process in that it most closely approximates the process of sample collecting and does not put any sort of pressure on the pump.

Leave a Reply

Want to join the discussion?Feel free to contribute!